What Factors Influence Makeup Bag Manufacturing Costs? (2026 Pricing Guide)

You have a great design, but the budget is a puzzle. Manufacturing quotes can be confusing, and hidden fees can easily derail your project and hurt your bottom line.

The main factors are materials, labor, and order quantity (MOQ). Customization, such as printing and hardware, also adds cost. Finally, you must account for "hidden" expenses like tooling, prototyping, and shipping logistics.

I see my role as more than just a manufacturer; I am a partner in co-creation. A big part of that partnership is providing clarity and transparency around costs. My mission is to help designers like you bring sustainable and beautiful products to market, and that means navigating the budget together. I have worked with many designers, from those at global luxury brands to founders of new indie lines, and the challenge is always the same: how to create the best possible product within a target price. Let's break down the costs so you can plan your next project with confidence.

What are the big three factors that shape your budget?

It is hard to plan your budget when you don't know the main cost drivers. You need to know where your money is going to make smart design decisions.

The three biggest factors are materials, labor, and order quantity (MOQ). Your choice of fabric is the largest variable. The complexity of the bag's design determines labor costs. Larger orders reduce the per-unit price.

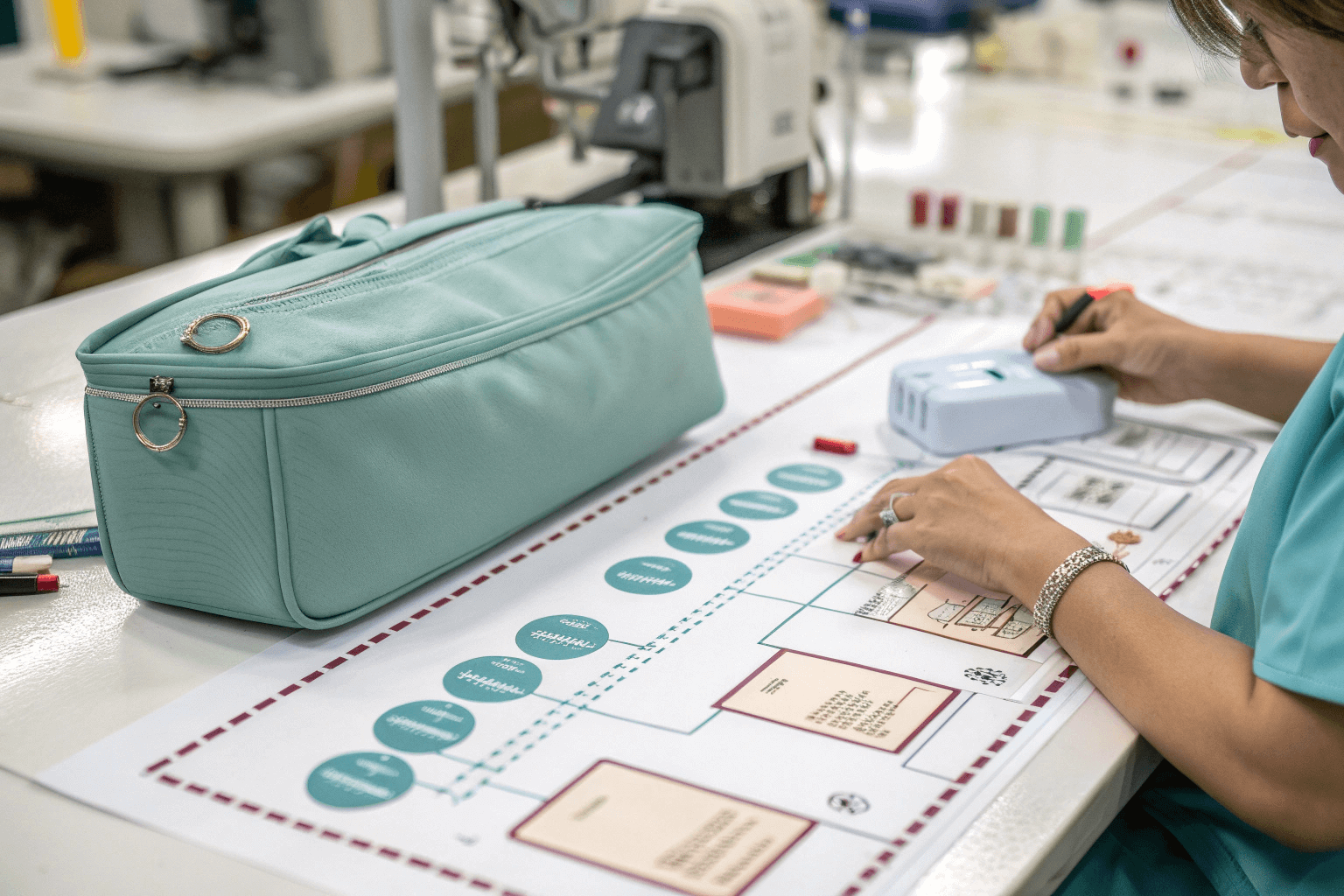

Understanding these three pillars is the key to managing your budget. I remember helping a designer, Jennie, who was developing a premium retail bag. Her initial material choice, a specialty plant-based leather, was beautiful but pushed the unit cost just over her target. We worked together, exploring alternatives. We found a high-grade, recycled PU vegan leather that had a similarly luxurious feel but was more cost-effective. This small change, made early in the process, brought the project back on budget without compromising the perceived quality. This is the kind of collaborative problem-solving that leads to a win-win result.

1. Materials: The Foundation of Your Cost

The fabric you choose is typically the single biggest factor in the final unit price.

- Cost Hierarchy: A standard polyester will be the most budget-friendly. Recycled materials like rPET cost a bit more. Organic cotton is next. High-quality PU vegan leathers are in the mid-to-high range, and innovative materials like cactus leather are at the premium end.

- Stock vs. Custom: Using a stock color that the factory already has is always cheaper than custom-dyeing a fabric to match a specific Pantone color, which involves higher costs and MOQs.

2. Labor: The Price of Complexity

The more time it takes a skilled worker to sew a bag, the more it will cost.

- Simple Pouch: A basic, flat pouch with one zipper is the fastest to produce and has the lowest labor cost.

- Complex Organizer: A structured bag with interior pockets, piping on the seams, and multiple compartments requires significantly more time and skill, which increases the labor cost.

| Feature | Low Labor Cost (Simple) | High Labor Cost (Complex) |

|---|---|---|

| Shape | Flat Pouch | Structured Box Shape |

| Seams | Basic Seams | Contrast Piping |

| Pockets | None | Multiple Interior Pockets |

| Construction | One Compartment | Lined with multiple dividers |

3. Order Quantity (MOQ): The Power of Scale

MOQ stands for Minimum Order Quantity. In manufacturing, buying in bulk lowers your price per unit.

- Economies of Scale: Setting up the machines and production line has a fixed cost. When you produce a larger quantity (e.g., 5,000 units vs. 1,000 units), that setup cost is spread across more items, making each one cheaper.

What is the cost impact of customization, printing, and hardware?

You know the big factors, but the small details are adding up. You are worried that your branding and hardware choices might unexpectedly inflate your budget.

Complex, multi-color printing costs more than simple, one-color logos. Custom-molded hardware requires a one-time mold fee. Premium metal zippers and pulls will always cost more than standard nylon or plastic options.

I believe that customization is what elevates a product from good to great. These details tell your brand story. But it is important to understand the associated costs so you can choose wisely. A client once wanted a custom zipper pull shaped like their brand's logo. It was a beautiful idea. I explained that there would be a one-time fee to create the metal mold for the pull. While this added to the initial project cost, they saw it as an investment in their brand identity. We balanced that cost by using a very efficient single-color screen print for the logo on the bag itself. It is all about making strategic choices to get the most impact for your budget.

The Cost of Branding

How you apply your logo directly affects the price.

- Screen Printing: This is often the most cost-effective method, especially for one or two-color designs.

- Digital Printing: Required for photographic images or designs with many colors and gradients. It is more expensive than screen printing due to the machinery and ink costs.

- Debossing/Embossing: This requires a custom metal stamp to be made, which is a one-time tooling cost. It creates a very subtle, high-end look.

Hardware Adds Up

The "jewelry" of your bag comes in different price tiers.

- Zippers: A standard nylon zipper is the base price. A metal zipper costs more, and a premium branded zipper (like YKK) is a top-tier choice.

- Zipper Pulls: Using a stock pull is included in the zipper price. A custom-molded metal pull requires a mold fee (often several hundred dollars) plus a higher per-piece cost.

Other Custom Details

- Custom Lining: A standard, solid-color lining is inexpensive. Printing a custom pattern or logo on the inside of the bag will increase the cost.

- Woven Labels: Adding a small, branded woven label inside the bag is a relatively low-cost way to add a premium touch.

What are the hidden costs to consider, like tooling, prototyping, and shipping?

You have a unit price from your manufacturer. But you know that is not the final number. You are concerned about surprise charges for things you didn't even think about.

Always budget for potential one-time tooling costs for custom molds or cutting dies. Factor in the cost of creating and shipping physical samples. Finally, remember that shipping, duties, and taxes are significant costs added after production.

Transparency is a core part of my "Global Win-Win" philosophy. I never want a client to be surprised by a bill. That is why we discuss all potential costs upfront during our initial design consultations. One of the most frequently overlooked costs is shipping. A client might be thrilled with a $2.00 per-unit manufacturing cost, but they forget that getting the product from our factory to their warehouse has its own price. Air freight is fast but expensive; sea freight is slower but much more affordable. Discussing these logistics early helps you build a complete and realistic budget for the entire project.

One-Time Tooling Costs

These are setup fees for creating custom components. They are paid once per design.

- Molds: Needed for custom plastic or metal parts, like a unique zipper pull or logo plate.

- Cutting Dies: If your bag has a very unique shape, a custom steel die may be needed to cut the pattern pieces accurately and efficiently.

- Printing Screens/Plates: A new screen is made for each color in a screen print. A metal stamp is made for debossing.

Prototyping and Sampling

Creating physical samples is a critical step, and it has associated costs.

- Sample Fee: Manufacturers often charge a fee for the first prototype to cover the cost of materials and the sample maker's time. This fee is sometimes refunded if you proceed with a bulk order.

- Shipping: Getting those samples to you requires international express shipping, which can be costly.

Shipping, Duties, and Taxes

This is a huge part of your final landed cost and is not included in the factory's unit price.

- Freight: The cost of transporting the goods from the factory. Sea freight is cheaper but slower (30-40 days). Air freight is faster but much more expensive.

- Duties and Tariffs: Taxes imposed by your country's customs office on imported goods. These vary greatly by country and product type.

- Inland Delivery: The cost to get the goods from the port to your final warehouse.

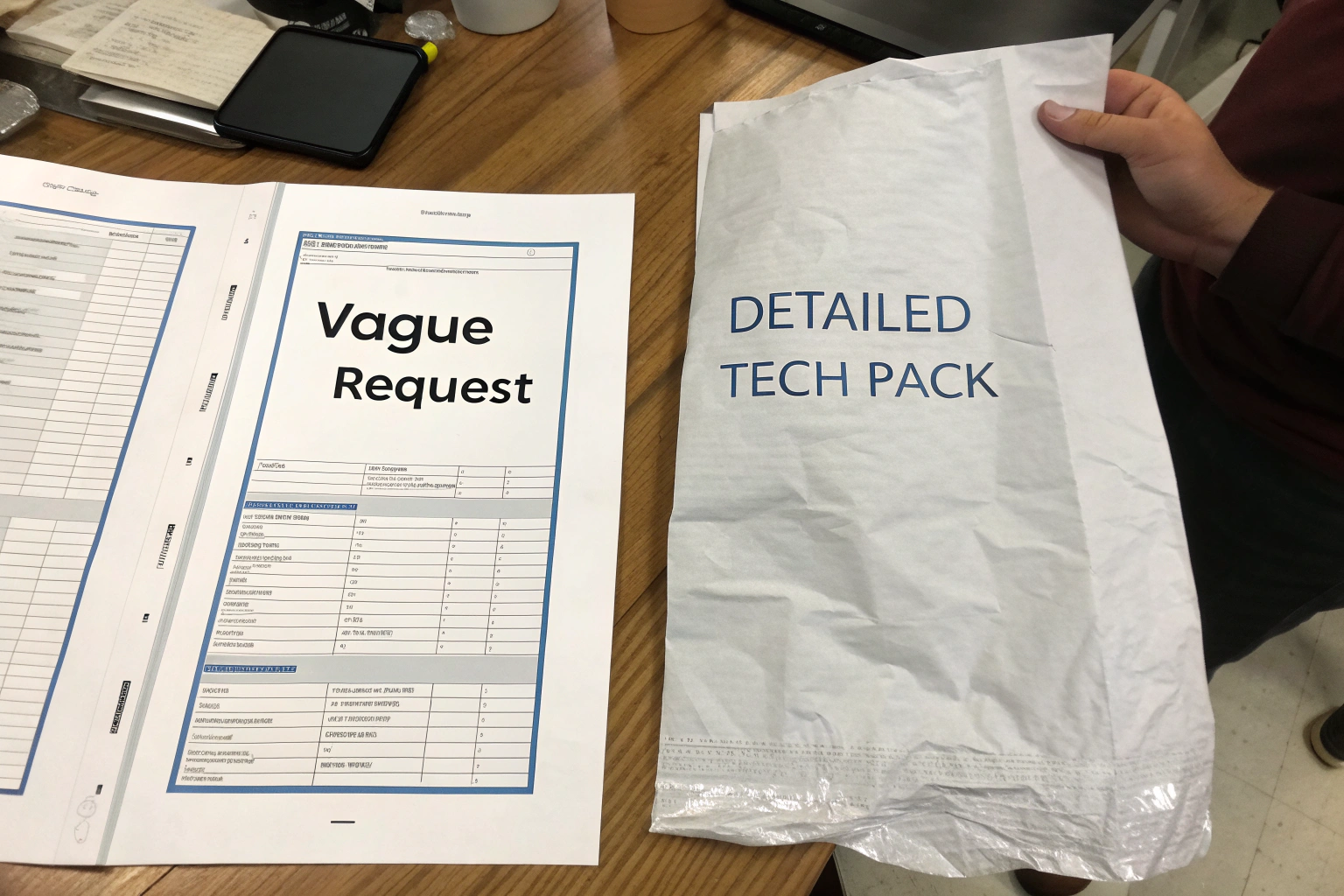

How do you get an accurate quote by preparing a tech pack your manufacturer will understand?

You are sending emails to factories but getting vague price ranges instead of firm quotes. This makes it impossible to compare options and finalize your budget.

To get an accurate quote, you must provide a detailed tech pack. It should include flat sketches with all measurements, a list of specific materials, exact Pantone color codes, and clear instructions for hardware and branding.

A tech pack is the language of production. The more clearly and thoroughly you speak that language, the better I can understand your vision and provide a precise quote. A request for "a medium-sized black makeup bag" leaves too many questions. What material? What kind of zipper? What's the lining? I would have to make many assumptions, leading to an inaccurate price. But when a designer like Jennie sends me a complete tech pack, it is a blueprint. I can see the exact dimensions, the specified rPET fabric, the Pantone color for the logo, and the custom zipper pull design. This allows my team to calculate the exact material usage and labor time. A great tech pack is the foundation of our co-creation process and the fastest way to a reliable quote.

The Anatomy of a Great Tech Pack

Think of your tech pack as the complete instruction manual for building your bag. It must eliminate all guesswork.

| Section | What to Include | Why It Matters for Costing |

|---|---|---|

| Technical Sketch | Flat drawings of all views (front, back, inside) with precise measurements | Allows us to calculate the exact amount of material needed. |

| Bill of Materials | A detailed list of every single component: fabric, lining, zipper, thread, labels | Each component has a cost, so a complete list is essential. |

| Colorways | Specify all colors using the Pantone (PMS) Matching System | Allows us to check if we have stock colors or need to quote custom dyeing. |

| Branding Details | Artwork files, placement, dimensions, and application method (e.g., screen print) | Different printing methods have vastly different costs. |

| Hardware Specs | Photos, dimensions, and desired finish (e.g., matte gold metal) for all parts | Specifies the quality level and cost of the components. |

Why Detail = Accuracy

When a manufacturer has all of this information, they can accurately calculate the two biggest variables: material consumption and labor time. They know exactly how much fabric is needed per bag and can estimate how many minutes it will take a sewer to complete one unit. This removes ambiguity and allows them to give you a firm, reliable price per unit.

Conclusion

Understanding manufacturing costs is about knowing the key drivers. By focusing on materials, labor, MOQ, and providing a detailed tech pack, you can create a realistic budget and a successful product.