The Complete OEM Guide: How to Manufacture Custom Cosmetic Bags?

Feeling overwhelmed by the idea of turning your design into a final product? The OEM manufacturing process seems full of technical terms and hidden steps, leaving your brilliant ideas stuck on paper.

Manufacturing your custom bag is a clear, step-by-step process. It starts with a detailed tech pack, followed by material selection, sampling, and understanding key terms like MOQ, before moving to mass production, quality control, and shipping. A good partner guides you through it all.

I've spent over three decades helping brand designers turn their visions into millions of beautiful, functional bags. I've met countless talented designers, just like Jacky, who have amazing ideas but feel intimidated by the world of manufacturing. The jargon, the logistics, the quality control—it can feel like a lot. But I'm here to tell you that it's a manageable, and even exciting, journey when you have the right partner. My goal is to demystify the process for you. Let's walk through the key questions every designer asks, and I'll share the simple, direct answers I've learned from a lifetime on the factory floor.

What Do You Need to Get Started?

Eager to begin manufacturing but unsure what to provide your factory? Sending incomplete ideas often leads to endless email chains, wasting precious time and delaying your product launch.

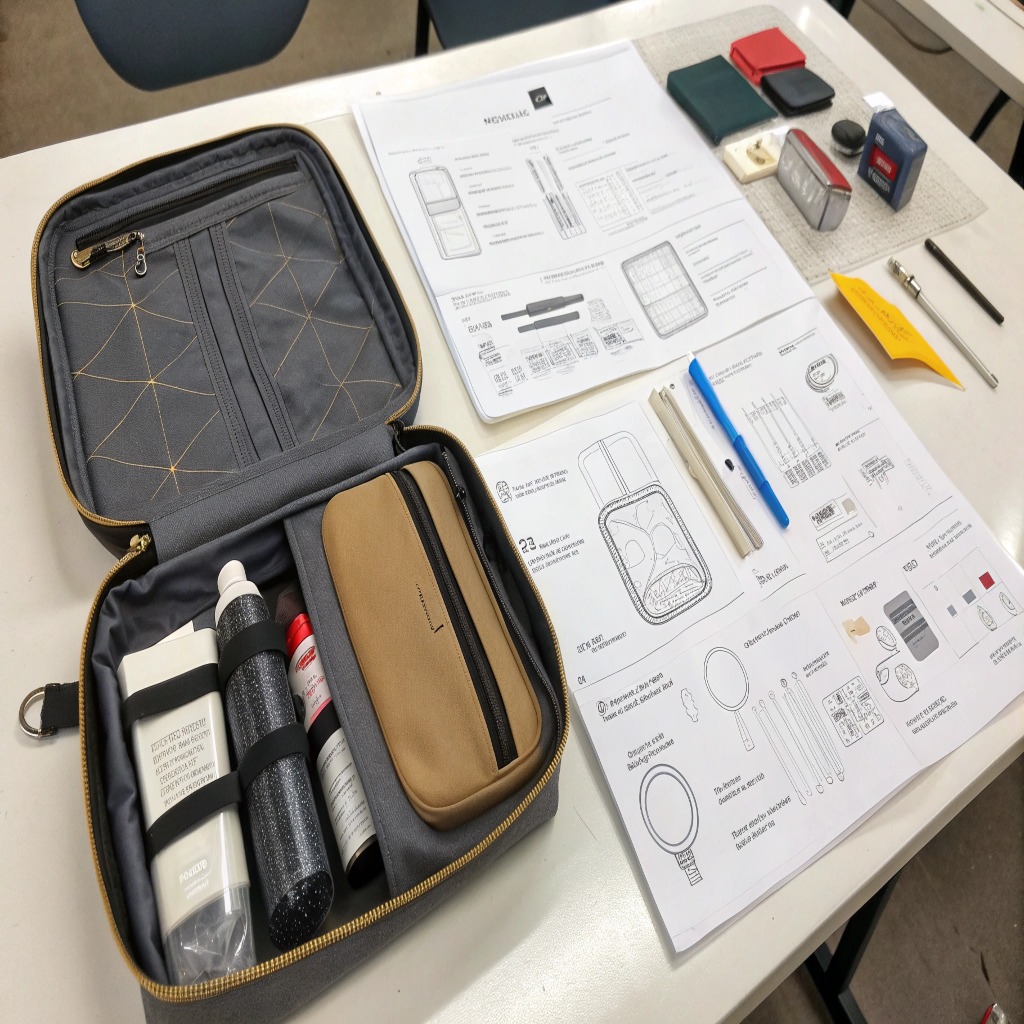

To get started, you need a "tech pack" or a detailed design brief. This is the single most important document, containing your bag's dimensions, material choices, construction details, and branding artwork. The more detail you provide, the better we can bring your vision to life.

A tech pack is the blueprint for your product. Think of it as the instruction manual we use to build your bag. While a simple sketch is a great start, a detailed tech pack ensures there’s no room for error. It's the key to getting an accurate quote and a perfect first sample. A good tech pack should always include: a technical drawing with precise dimensions (L x H x W), clear callouts for materials (like "12oz GRS-certified rPET canvas" for the outer and "210D polyester" for the lining), specifications for hardware like zippers and pullers, and your logo artwork with Pantone colors and placement details. I remember working with a designer whose initial sketch was great, but the tech pack was what made it a success. By documenting everything, from the recycled cotton fabric to the custom-molded zipper pull, we were able to create his perfect sample on the very first try.

How Do You Choose the Right Materials for Your Brand and Budget?

Worried about choosing materials that are too expensive for your budget or too cheap for your brand's image? This difficult decision can make or break your product's success and profitability.

Balance your brand identity with your target cost. Canvas is durable and affordable, nylon is lightweight and practical, and vegan leather offers a premium feel. Details like zippers and liners also impact cost but are crucial for a quality user experience.

Choosing the right materials is where your brand's story begins. At Rivta, our mission is to create beautiful products with a conscience, so we often start with sustainable options. For an eco-conscious, natural feel, we might suggest organic cotton or our innovative bamboo fiber fabrics. For a sleek, modern cosmetic line, a high-quality recycled PET (rPET) material or a premium PU (vegan) leather is a fantastic choice. But the main fabric is only part of the story. The details—the "trims"—are what elevate a good bag to a great one. A standard nylon zipper is cost-effective, but a sturdy, smooth metal YKK zipper communicates durability and quality. A custom-molded zipper pull with your brand's icon adds a unique touch. And never underestimate the lining! I always recommend a wipe-clean material for cosmetic bags; it adds immense practical value for the end user.

| Material | Best For | Feel & Function | Cost Tier |

|---|---|---|---|

| Canvas/Cotton | Eco-conscious, Casual Brands | Durable, natural, highly printable | $ |

| Nylon/rPET | Travel, Modern, Practical Brands | Lightweight, durable, water-resistant | $$ |

| PU/Vegan Leather | Premium, Luxury, Vegan Brands | Sleek, smooth, elegant | $$$ |

How Can You Be Sure the Final Product Will Look Like Your Design?

Anxious that the final bulk order won't match the design you approved? This is a common fear, as a bad production run can lead to wasted inventory and financial loss.

The key is the sampling process. You should always review and approve pre-production samples (PPS) before authorizing mass production. This physical sample is your guarantee that the factory understands every detail of your design, from stitching to color.

The sample is your insurance policy. No matter how detailed your tech pack is, nothing replaces holding a physical version of your bag in your hands. This is the most critical checkpoint in the entire OEM process. At our factory, this is a multi-stage process. First, we might create an initial prototype to confirm the structure and size. Once the pattern is perfected, we create a "pre-production sample" (PPS). This is the hero sample. It is made with the exact final materials, correct logo application, and all the specified hardware and trims. This is your chance to test it, feel it, and scrutinize every detail. Only after you—the client—have given your explicit approval on the PPS do we move forward. This step eliminates any surprises and ensures that the 10,000 bags we produce will be identical to the one you signed off on. It is our commitment to you that what you approve is what you will receive.

What Are the Key Terms You Need to Know?

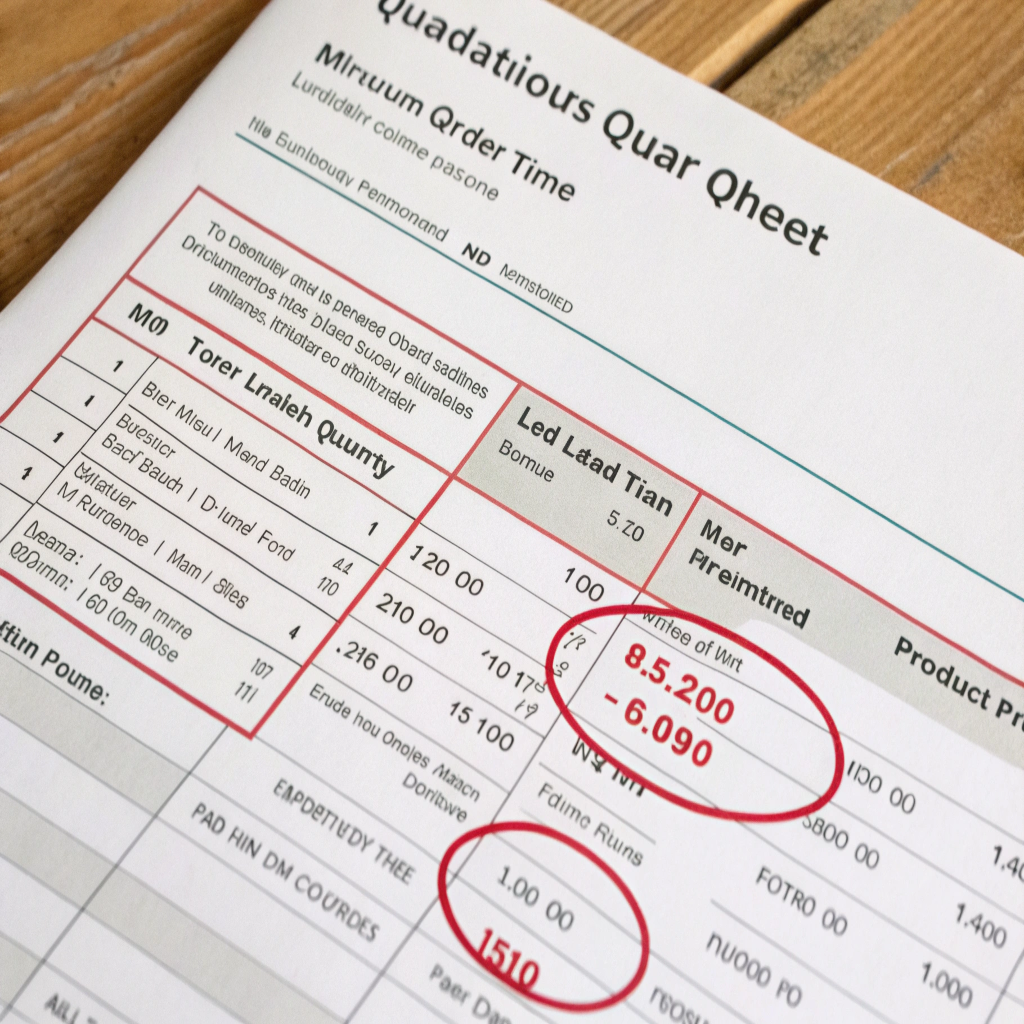

Confused by the jargon on your quotation sheet, like 'MOQ' and 'Lead Time'? Misunderstanding these terms can lead to budget mistakes and incorrect timelines, causing stress for your team.

You must understand two key terms: MOQ (Minimum Order Quantity), the smallest number of units you can order, and Lead Time, the time from order confirmation to shipment. These are influenced by material availability and production complexity.

When you receive a quotation from a manufacturer, it's more than just a price. It's a summary of the project's key parameters. Let's decode the two most important ones.

1. MOQ (Minimum Order Quantity): This is the smallest order size the factory can accept for your specific design. Why does this exist? Because we have to buy fabric by the roll and dye colors by the vat, and our machines need to be set up specifically for your project. The MOQ ensures we can cover these fixed costs and run production efficiently. At Rivta, we always try to work with brands to find an MOQ that works, sometimes by suggesting stock materials to start.

2. Lead Time: This is the total time it will take to produce your order, usually counted from the day you approve the pre-production sample. A typical lead time might be 45-60 days. This period covers ordering raw materials (around 15-20 days) and mass production, including cutting, printing, sewing, and packing (around 30-40 days). It's crucial to factor this into your launch timeline.

What Happens During Mass Production?

Ever wonder what actually happens inside a factory during mass production? The process can seem like a black box, leaving you uncertain about how your product is really being made.

Mass production is an assembly line process. It begins with cutting the fabric panels based on approved patterns. Then, panels are printed or embroidered. Next, skilled workers sew the pieces together, add hardware, and assemble the final bag before it goes to Quality Control.

Once you've approved that perfect pre-production sample, our factory floor buzzes into action. It's a carefully choreographed dance. First, our pattern masters use your design to create precise cutting molds. Huge rolls of your chosen fabric—perhaps our sustainable rPET canvas—are laid out on long tables, ready for the cutting machines to create hundreds of identical panels at once. Next, these flat panels go to the branding department. This is where your logo comes to life through screen printing, embroidery, or debossing. After branding, the pieces move to the sewing lines. Here, our skilled skilled workers work in teams. One person might sew the main body, another attaches the zipper, a third adds the lining, and a fourth sews on the branded label. This assembly-line method ensures consistency and efficiency. Finally, each bag gets its finishing touches—attaching custom zipper pulls and undergoing the first round of quality checks before being sent for final inspection and packing.

How Do You Guarantee the Quality of 10,000 Units?

Worried that the quality of your bulk order won't match the pristine sample you approved? It's a valid concern; ensuring consistency across thousands of units is a major manufacturing challenge.

Quality is guaranteed through a multi-point Quality Control (QC) process. This includes inspecting raw materials, checking pieces during production (in-line QC), and a final, thorough inspection of every single bag before it is packed for shipment.

For us, quality isn't just a final step; it's embedded in our entire process. We can't simply inspect quality at the end; we have to build it in from the beginning. Our QC process starts the moment raw materials arrive. We inspect fabric rolls for flaws and check that zippers and hardware match the approved sample. The second checkpoint is "in-line QC." As the bags move down the sewing line, team leaders are constantly checking the work at each station to catch any issues early. The most critical stage, however, is the final inspection. Before a single bag is put into a polybag, it goes to our dedicated final QC team. They check every single unit against a "golden sample" (the approved PPS). They check for correct dimensions, stitching quality, logo placement, and hardware function. Any bag with even a minor defect is pulled from the line. This rigorous, multi-step process is our promise to you that every bag in your order will meet the high standard you expect.

How Does the Product Get From the Factory to Your Warehouse?

Your bags are finished, but how do they get from a factory overseas to your doorstep? The world of international shipping and customs can seem incredibly complex and expensive.

The process is managed through your choice of Incoterms, typically FOB or EXW. Your freight forwarder handles the logistics, including ocean or air freight, customs clearance, and duties, to calculate your final "landed cost" and deliver the goods.

Getting your products home is the final piece of the puzzle. The first thing to understand is the "Incoterm" on your quote. Most often, you'll see FOB (Free On Board). This means our price includes manufacturing the bag and delivering it to the ship at our local port. From that point on, the cost and responsibility are yours. You'll hire a "freight forwarder," a logistics partner who manages the rest of the journey. They will book space for your goods on acontainer ship (ocean freight) or airplane (air freight). They handle the insurance and all the customs paperwork, both in the origin country and in your home country. You will have to pay for the freight, insurance, plus any import duties and taxes your country charges. The sum of our FOB price plus all these other charges is your true total cost, often called the "landed cost." A good freight forwarder will help you estimate these costs in advance so there are no surprises.

Why Should You Partner with Rivta for Your OEM Project?

Looking for a manufacturer but unsure who to trust? You need a partner who is not only capable but also transparent, communicative, and aligned with your brand's values, especially regarding sustainability.

With over three decades of experience, Rivta is more than a manufacturer; we are your partner. We offer expertise in sustainable materials, total transparency in our process, and a deep commitment to bringing your vision to life with the highest quality standards.

Choosing a manufacturing partner is the most important decision you'll make. I founded Rivta on a simple principle: we love to help people improve their lives. This extends to our clients, our workers, and our planet. When you work with us, you're not just another order number. You're a partner. We bring 30+ years of expertise to your project, guiding you on the best materials and construction techniques. We are deeply committed to sustainability, specializing in verified recycled and natural materials like rPET, organic cotton, and bamboo fiber. We believe in total transparency; you'll be informed at every step, from sampling to shipping. Our expertise in serving the beauty industry means we understand your needs for both aesthetics and function. We are here to answer your questions, solve problems, and make the manufacturing process smooth and successful for you.

Conclusion

Manufacturing custom bags is a clear, manageable process. With a detailed tech pack and a trustworthy partner like Rivta, you can confidently turn your vision into a quality product for your brand.