PVC vs. RPET vs. TPU: Which Clear Material is Best for Your Cosmetic Bags?

You need a clear material for your next cosmetic bag. But the options—PVC, RPET, and TPU—all look similar, making the choice confusing and risky for your brand.

RPET is the best eco-friendly option, ideal for green brands. TPU offers a premium, soft feel for luxury markets. PVC is the lowest-cost choice for budget-focused projects. The best material depends on your brand's target cost, quality, and sustainability goals.

My "Green Mission, Global Win-Win" slogan is the heart of my business. It means I am committed to finding the perfect solution that benefits both your brand and the planet. I often talk with talented designers like you, Jennie, who are trying to balance beautiful design with responsible choices. Choosing a clear material is not just a technical decision; it is a statement about your brand's identity. I see it as a co-creation process, where we work together to select a material that perfectly aligns with your vision. Let's look at these three materials up close.

How do you compare the cost, durability, and feel?

You need the quick facts on these materials. Data sheets are dense and confusing, and you just want a simple comparison of how they will perform and what they will cost.

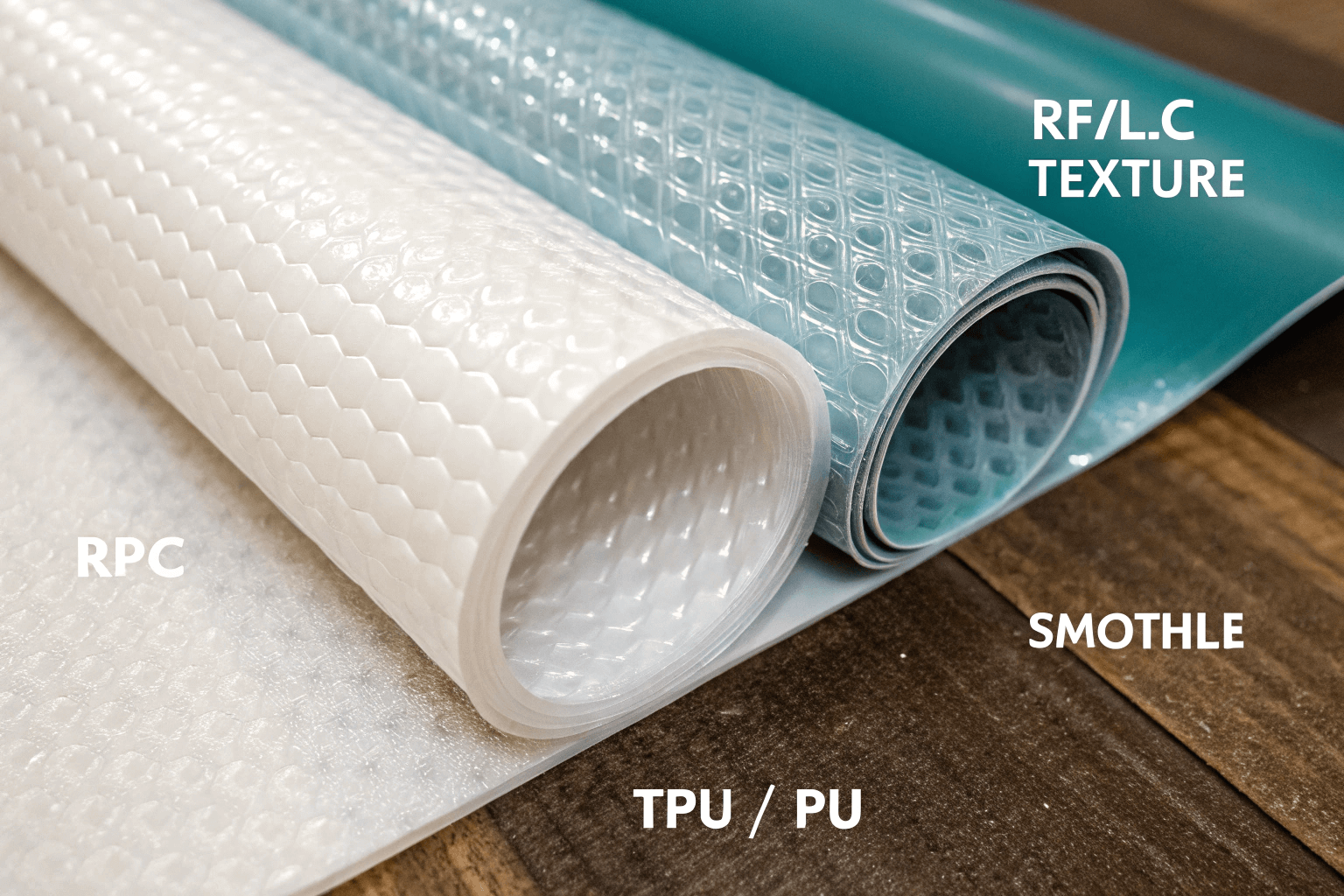

PVC is the cheapest but feels stiff and can crack in the cold. RPET is a mid-cost, rigid material that holds its shape well. TPU is the most expensive but feels soft, premium, and is extremely durable.

I handle these materials every day in my factory, so I know their personalities well. The "feel" of a material is so important. A luxury skincare brand I work with once requested samples of the same bag in both PVC and TPU. When they held them, the decision was instant. The soft, flexible, and premium feel of the TPU bag immediately felt aligned with their high-end products. The PVC version, while functional, simply did not communicate the same sense of quality. This experience showed me that the material itself is a key part of the customer's brand experience. It is a technical choice that has a very emotional result.

A Buyer's Technical Comparison

| Feature | PVC (Polyvinyl Chloride) | RPET (Recycled PET) | TPU (Thermoplastic Polyurethane) |

|---|---|---|---|

| Cost | $ (Lowest) | $$ (Mid-range) | $$$ (Highest) |

| Feel | Stiff, can feel cheap, less flexible. | Rigid, structured, holds its shape. | Soft, very flexible, smooth, premium feel. |

| Durability | Good. Can become brittle and crack in cold weather. Scratches moderately. | Very good. Excellent scratch resistance. Less flexible, so not prone to stretching. | Excellent. Superior abrasion and puncture resistance. Stays flexible in extreme cold. |

| Clarity | Good to excellent. Can yellow over time when exposed to UV light. | Excellent. Very high optical clarity that remains stable over time. | Excellent. Very clear and stable, but can have a slight "honey" tint in thicker grades. |

| Printability | Very good. Screen printing and other methods adhere well. | Good. Best for structured bags where the print surface is flat. | Very good. Requires specific inks for best adhesion and flexibility. |

How does your material choice impact sustainability and brand image?

You know your material says something about your brand. Choosing the wrong one could send a message that clashes with your company's values and disappoint your eco-conscious customers.

RPET is the clear sustainability champion, aligning your brand with recycling. TPU is a better, non-toxic plastic choice. PVC is the least eco-friendly and can create a negative brand image for conscious consumers.

My mission is to help brands like yours find a win-win solution. This means a great product that also has a great story. For designers like Jennie, who focus on circular design principles, this is everything. She will not even consider PVC because it conflicts with the sustainable story she helps brands build. Instead, we focus on materials like GRS-certified RPET. We can then create a marketing story about how many plastic bottles were saved from the landfill to create the new cosmetic bag. This transforms the product from a simple container into a symbol of the brand's commitment. It is not just a bag; it is a statement. This is how a simple material choice can build a powerful connection with your customers.

The Sustainability Story Behind Each Material

- PVC (The Problematic Plastic): PVC's full name is Polyvinyl Chloride. The "chloride" part is chlorine, which creates environmental issues during its lifecycle. Its production and disposal can release harmful toxins called dioxins. It also contains chemical softeners called phthalates, which are a health concern. It is not easily recycled and is a target for environmental groups. For a brand focused on wellness or clean beauty, using PVC can feel like a major contradiction.

- RPET (The Circular Economy Champion): RPET stands for Recycled Polyethylene Terephthalate. It is made from post-consumer plastic, primarily soda and water bottles. By choosing RPET, your brand actively participates in the circular economy. You are helping to reduce landfill waste and using less energy than required for virgin plastic. Look for Global Recycled Standard (GRS) certification to guarantee the recycled content and responsible production. This is the most powerful story for any eco-conscious brand.

- TPU (The Premium, Better Plastic): TPU stands for Thermoplastic Polyurethane. It is seen as a much more benign plastic than PVC. It is free of chlorine and phthalates, so it does not have the same toxicity concerns. Its superior durability also means the product lasts longer, reducing waste. It is also recyclable in certain industrial streams. For a luxury brand, TPU offers a way to get premium performance without the environmental baggage of PVC.

How do you match the right material to your target market?

You have a specific customer in mind. The material you choose must meet their expectations for quality, style, and price, or they simply will not buy it.

Use PVC for mass-market giveaways where price is the only factor. Choose RPET for the broad, eco-aware mid-market. Select TPU for the high-end, luxury consumer who demands premium quality and feel.

Understanding your customer is key to our co-creation process. I often ask clients not just about the bag, but about the person who will use it. Is this a free gift-with-purchase for a mass-market brand? Then the low cost of PVC makes sense. Is this for a clean-beauty startup that grew its following on Instagram? Their customers expect sustainable choices, so RPET is the only way to go. Is it for a high-end skincare line sold at luxury retailers? That customer expects the best of everything, so the beautiful feel and durability of TPU are worth the investment. By matching the material to the market, we create a product that feels right and sells well.

Aligning Material with Customer Profile

- Targeting the Mass Market with PVC: This consumer is driven by price and function. They are looking for a basic, useful item, often as a freebie or a low-cost add-on. Think promotional giveaways at a large event or a simple travel bag sold in a discount store. The brand story is less important than the utility and the rock-bottom price, making PVC the most logical economic choice.

- Targeting the Conscious Mid-Market with RPET: This is a huge and growing group of consumers. They are informed, read labels, and follow brands that share their values. They use products from brands like Glossier or Fenty Beauty. They expect sustainability, and they are willing to pay a bit more for it. A clear bag made from recycled bottles is a perfect product for them. It is trendy, functional, and makes them feel good about their purchase.

- Targeting the Luxury Market with TPU: This consumer demands perfection. They value craftsmanship, long-lasting quality, and a premium tactile experience. They are buying a high-end serum or a luxury fragrance. The packaging and accessories must reflect that same level of quality. The soft, supple feel of TPU, combined with its durability and non-toxic properties, makes it the only choice for a brand that wants to communicate uncompromising luxury.

What should you know about manufacturing before choosing PVC, RPET, or TPU?

You are ready to pick a material. But how it is manufactured can affect the final quality. You need to know if the factory you choose has the right skills for the job.

PVC is the easiest to manufacture, using standard welding techniques. The rigidity of RPET requires more skill in sewing. TPU's unique flexibility and strength demand specialized high-frequency welding equipment and expertise for the best results.

As a manufacturer, this is where my team's expertise really shines. Every material has its own personality on the production line. When a client chooses a material, our co-creation process continues. We have to design the product in a way that respects the material's properties. For example, if a designer wants a bag with many complex, soft curves, I would guide them toward TPU, which handles this beautifully. If they choose rigid RPET, I would suggest a more structured, geometric design where the material's stiffness becomes a strength. A great manufacturing partner does not just take your order; they collaborate with you to ensure your design and your material work together perfectly.

Manufacturing Nuances for Each Material

- Working with PVC: PVC is the old standby for a reason. It is very easy to work with. It responds perfectly to high-frequency (HF) welding, which uses electricity to fuse the plastic sheets together. This creates very strong, clean, and waterproof seams. Most factories with experience in clear bags are well-equipped to handle PVC.

- Working with RPET: Clear RPET film is much more rigid than PVC or TPU. This makes it great for creating bags that stand up on their own, but it can be brittle under stress. Sewing is the more common construction method, and it requires careful handling to avoid cracking at the seams, especially on tight corners. It is less suitable for complicated shapes that require a lot of flexibility.

- Working with TPU: TPU is the material of choice for premium construction, but it requires the most skill. It welds beautifully with HF machines, creating seams that are even stronger and more flexible than PVC welds. However, its softness and stretchiness mean that workers need to be very skilled to handle it during sewing and assembly to prevent puckering. Working with TPU is a sign of a high-quality, technically proficient factory.

Conclusion

Choosing between PVC, RPET, and TPU comes down to your brand's priorities. Align your choice with your goals for cost, quality, and sustainability to create a product that truly represents you.