Views : 605

Author : Lina

Update time : 2025-03-25 20:20:40

How Manufacturing Processes Support Sustainable Cosmetic Bags

For brands and sustainability-focused professionals seeking eco-friendly cosmetic bags, understanding the manufacturing processes behind them is key to aligning with environmental goals and consumer expectations. As a large-scale manufacturer based in Dongguan City since the 1990s, Rivta specializes in custom-made, mid-to-high-end eco-friendly cosmetic bags, offering original designs, innovative material solutions, and high-quality production. But how do these processes ensure sustainability? This guide provides the answers, tailored to industry leaders looking for reliable, green solutions.

Before diving in, consider these essential questions:

- How can manufacturing processes reduce the environmental footprint of cosmetic bags?

- What materials and techniques best support sustainability without compromising quality?

- How does a well-established supply chain enhance eco-friendly production?

We’re here to deliver a comprehensive look at how Rivta’s manufacturing processes create sustainable cosmetic bags for worldwide brands. Let’s explore:

- Understanding Our Approach

- Core Manufacturing Processes for Sustainability

- A Closer Look at Rivta’s Sustainable Practices

- Why Rivta Stands Out as a Premier Eco-Friendly Manufacturer

- Future Trends in Sustainable Cosmetic Bag Manufacturing

- Conclusion

Stay tuned as we uncover the trade secrets behind sustainable cosmetic bag production, designed to empower your brand’s sustainability journey.

1. Understanding Our Approach

At Rivta, our understanding are built on over three decades of expertise, rigorous certifications (BSCI, SEDEX, ISO9001), and a dedication to eco-friendly innovation. This guide draws from:

- Industry trends in sustainable packaging and cosmetics.

- Rivta’s internal data on material sourcing and production efficiency.

- Feedback from global brands prioritizing sustainability.

- Collaboration with supply chain partners specializing in eco-friendly materials.

Our mission is to provide transparent, actionable information to help you make informed decisions about sustainable packaging solutions.

2. Core Manufacturing Processes for Sustainability

Sustainable cosmetic bag production relies on processes that minimize environmental impact while upholding quality. Here’s how manufacturing supports eco-friendliness:

Material Selection

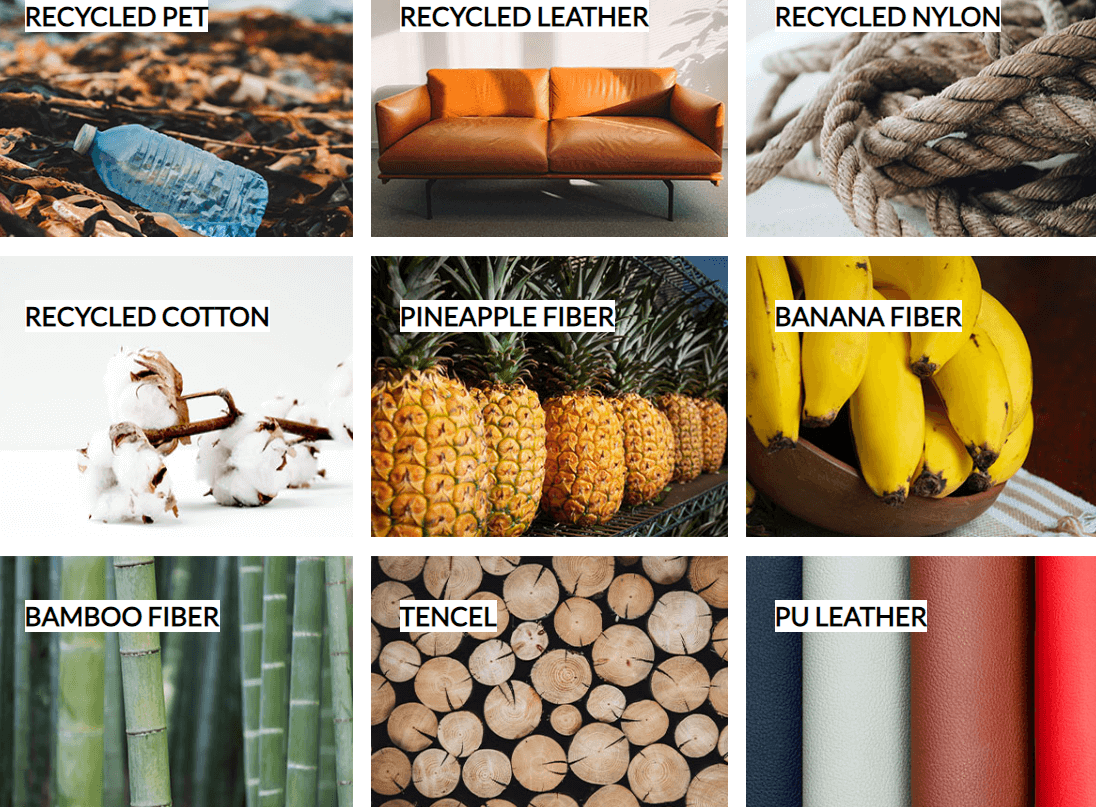

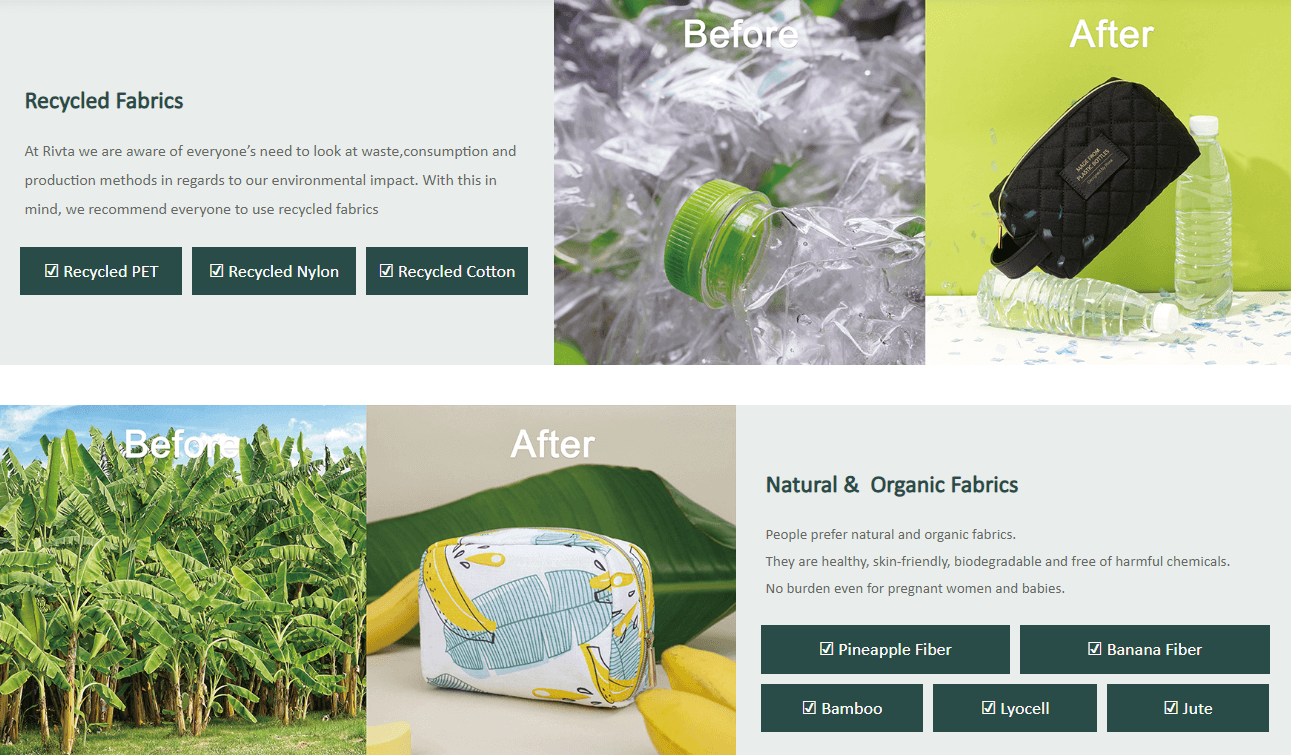

Eco-friendly materials are the foundation of sustainability. Rivta uses:

Recycled PET: Sourced from post-consumer plastics, ideal for durable, water-resistant bags. For example, converting 1,000 plastic bottles into RPET fabric prevents approximately 30 kg of plastic waste from reaching landfills.

Organic Cotton: Renewable and biodegradable, perfect for premium, everyday designs. Compared to conventional cotton, organic cotton uses 91% less water and avoids synthetic pesticides.

Innovative Alternatives: Biodegradable fabrics and upcycled materials tailored to brand needs, such as apple leather or pineapple fiber textiles, offer sustainable yet luxurious solutions.

These choices reduce reliance on virgin resources, meeting the demands of eco-conscious markets.

Energy and Waste Efficiency

Efficient processes lower the carbon footprint:

Energy Optimization: Advanced machinery reduces energy use during production, cutting emissions by up to 30% in comparison to traditional processes.

Waste Reduction: Scrap materials are reused or recycled, minimizing landfill waste. For instance, leftover fabric from one production cycle can be repurposed into accessory pouches or lining materials.

Water Reuse: Systems recycle water in manufacturing, conserving resources. Facilities implementing water recycling save an estimated 2,000 liters per production batch.

Automation ensures precision, delivering consistent quality with fewer resources—a hallmark of large-scale, sustainable operations.

Circular Design Principles

Designing for a circular economy extends product lifecycles:

Recyclability: Bags are crafted for easy disassembly and recycling.

Durability: High-quality standards ensure longevity, reducing replacement frequency.

Ethical Sourcing: Certified suppliers provide materials meeting global sustainability benchmarks, such as the Global Recycled Standard (GRS) and OEKO-TEX certification.

These practices support brands aiming for circular solutions and long-term environmental impact.

3. A Closer Look at Rivta’s Sustainable Practices

Founded in the 1990s in Dongguan City, Rivta has grown into a leader in eco-friendly cosmetic bag manufacturing. Here’s how our processes deliver:

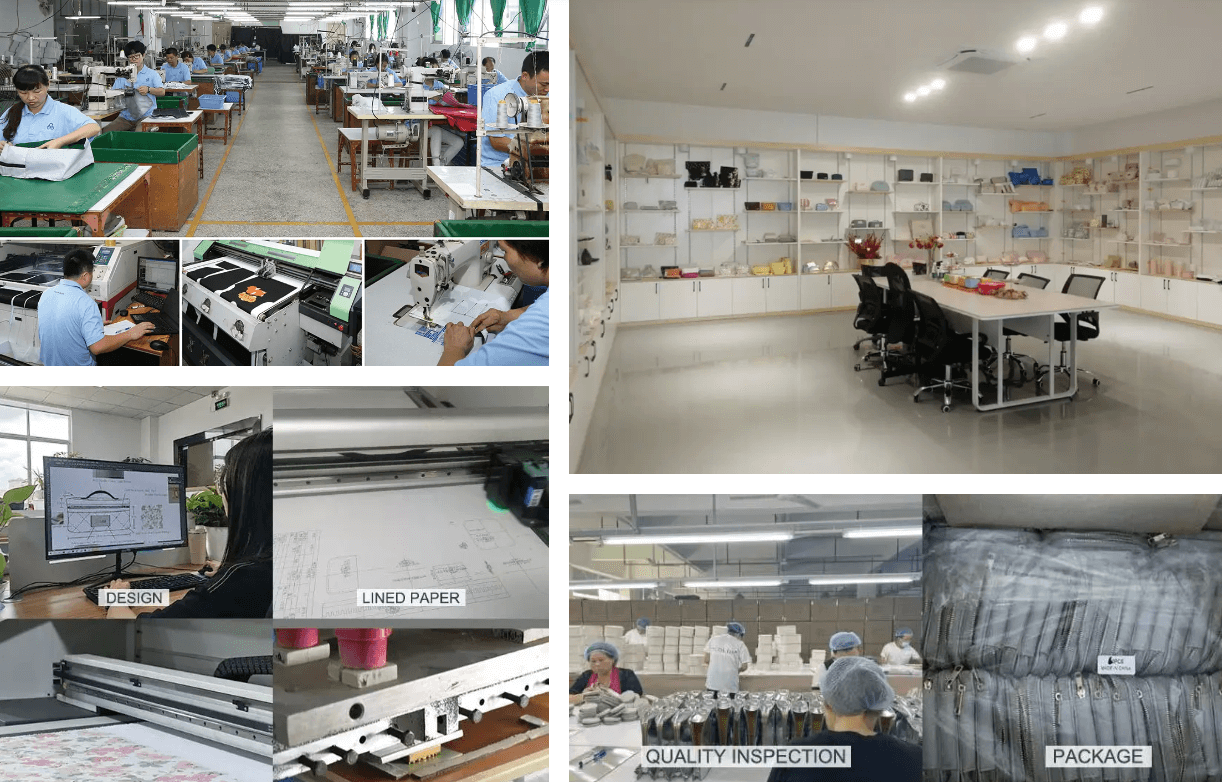

Innovative Design and Customization

- Original Designs: Our in-house team creates unique, brand-aligned designs, avoiding generic templates.

- Customization: Tailored solutions meet specific packaging needs, from size to branding.

- Eco-Innovations: We pioneer materials like apple leather or hemp blends, pushing sustainability forward.

Supply Chain Excellence

- Established Network: A robust supply chain ensures consistent access to eco-friendly materials.

- Certified Partners: Suppliers adhere to BSCI and SEDEX standards, guaranteeing ethical practices.

- Local Advantage: Proximity to Dongguan’s manufacturing hub streamlines logistics, cutting emissions.

Quality Assurance

- Certifications: ISO9001 ensures rigorous quality control, vital for mid-to-high-end markets.

- Testing: Each bag undergoes durability and sustainability assessments, meeting global standards.

- Scalability: Large-scale facilities handle high-volume orders without sacrificing eco-commitments.

These strengths position Rivta as a trusted partner for brands balancing sustainability with premium quality.

4. Why Rivta Stands Out as a Premier Eco-Friendly Manufacturer

Rivta’s unique position in the industry comes from:

- Experience: Over 30 years of refining eco-friendly manufacturing.

- Innovation: Cutting-edge materials and designs distinguish us from competitors.

- Scale: Large-scale production meets the demands of global brands efficiently.

- Certifications: BSCI, SEDEX, and ISO9001 reflect our commitment to ethics and quality.

For brands seeking a manufacturer that delivers on sustainability and excellence, Rivta offers a proven track record of innovative designs and eco-friendly processes, ensuring your products stand out in a competitive market.

5. Future Trends in Sustainable Cosmetic Bag Manufacturing

Sustainability in manufacturing continues to evolve, with emerging trends shaping the future:

Bio-Based Materials: More brands are adopting plant-based leathers and biodegradable textiles.

Carbon-Neutral Manufacturing: Factories are integrating renewable energy and carbon offset strategies.

Smart Recycling Technologies: AI-powered sorting and material recovery enhance recycling efficiency.

Supply Chain Transparency: Brands demand traceability, using blockchain for tracking eco-certifications.

Rivta is at the forefront of these innovations, continuously adapting to meet the highest sustainability standards.

6. Conclusion

Manufacturing processes are the backbone of sustainable cosmetic bags, from eco-friendly material selection to energy-efficient production and circular design. At Rivta, we’ve perfected these processes since the 1990s to serve worldwide brands, offering custom-made, mid-to-high-end solutions that prioritize both quality and the planet.

Ready to elevate your packaging with sustainable cosmetic bags? Contact us at Rivta’s Contact Page to explore how our innovative designs and eco-friendly manufacturing can support your vision. We’re here to partner with you every step of the way.

Related News

Clear Cosmetic Bags Wholesale: The B2B Buyer's Guide to Bulk Pricing & Factory Sourcing?

Sep .26.2025

Finding a reliable supplier for clear cosmetic bags can feel overwhelming. You face inconsistent quality and confusing pricing, making it hard to trust you're getting the best value for your brand.

Buying Cosmetic Bags in Bulk: The Complete 2025 Guide for B2B Buyers?

Sep .25.2025

Sourcing quality cosmetic bags can feel overwhelming. Finding a reliable, eco-conscious partner is even harder. This guide will help you navigate the process and find the perfect match for your brand.

The Top 7 Reasons Why Partnering with a Sustainable Custom Bag OEM Elevates Your Brand

Sep .24.2025

In a saturated market, your beauty brand needs to stand out. A high-quality, custom gift-with-purchase (GWP) is a proven way to capture consumer attention and build loyalty far beyond the initial sale.

How to Find the Ultimate Toiletry Bag Manufacturer for Your US Business in 2025?

Sep .24.2025

Finding a reliable supplier can feel impossible. You're dealing with inconsistent quality, poor communication, and delays. This guide will show you how to find the perfect manufacturing partner for your brand.