From Raw Material to Flawless Finish: The Manufacturing Process of a Quality Clear Makeup Bag?

You see a finished clear bag, but the journey it took is a mystery. This makes it hard to judge if you're getting a quality product or one that will crack, tear, and tarnish your brand's reputation.

A quality clear makeup bag is the result of a precise, multi-stage manufacturing process. It starts with sourcing superior materials like TPU, followed by precision cutting, expert assembly using techniques like high-frequency welding, and ends with rigorous, multi-point quality control to ensure a flawless finish.

The difference between a premium bag and a cheap one isn't just the price; it's the hidden process. I’ve walked countless brand founders through our factory, and their eyes always open wide. They see that it's not just one machine spitting out bags. It's a symphony of skilled hands and precise technology. I remember Alisa, the founder of an Australian natural care brand, being amazed. With her designer's eye, she appreciated how every single step, from inspecting the raw TPU to the final stitch on the zipper, contributed to the luxurious feel of the final product. She realized that to get a flawless finish, you need to understand and control the entire journey. Let's walk through that journey together.

Why choosing the right clear makeup bag factory matters for quality?

You need a manufacturing partner, but many factories look the same online. You are afraid of choosing the wrong one and ending up with inconsistent quality, missed deadlines, and a product that damages your brand's image.

Choosing the right factory is critical because they are the guardian of your product's quality. A good factory provides expertise in materials, skilled craftsmanship for consistency, and reliable communication, directly impacting your brand’s reputation and customer satisfaction.

Your factory isn't just a supplier; they are an extension of your brand. When a customer holds your bag, they are feeling the work of the factory you chose. The right partner understands your vision. For Alisa’s sustainable brand, choosing a factory that professional in eco-friendly materials like TPU was essential. A factory focused on cheap PVC couldn't have met her standards. A quality-focused factory invests in trained workers who can produce consistent, high-quality stitching and assembly. A poor factory might use unskilled labor, leading to bags that fall apart. Furthermore, a good partner acts like one. They communicate clearly, provide accurate samples, and stick to production timelines. This reliability is priceless. In essence, your factory choice determines whether your physical product lives up to the promise of your brand.

| Aspect | A Quality Factory (like Rivta) | A Low-Cost Factory |

|---|---|---|

| Material Expertise | Guides you to superior, eco-friendly materials (TPU). | Pushes the cheapest option (PVC), regardless of quality. |

| Craftsmanship | Employs skilled, stable workforce for consistent results. | High worker turnover leads to inconsistent, sloppy work. |

| Communication | Proactive, clear communication and reliable timelines. | Poor English, missed deadlines, and excuses. |

| Quality Control | Multi-stage QC process to catch errors early. | Final check only (if any), letting flawed products ship. |

Inside a clear makeup bag factory: from material selection to cutting?

You've approved a design, but how does that turn into physical pieces? You worry that mistakes made early in the process, like using bad materials or inaccurate cutting, will ruin the entire batch.

The process begins with sourcing and inspecting premium raw materials like TPU. Once approved, the material is precisely cut into panels using steel dies or lasers to ensure every single piece is perfectly uniform, which is critical for flawless assembly.

Everything starts with the raw material. At our factory, the first step is always inspection. When a new roll of TPU arrives, we unroll sections of it over a lightbox. We are looking for any imperfections: scratches, bubbles, or inconsistencies in thickness. A tiny flaw here can ruin the look of a finished bag. Only perfect material moves on to cutting. For cutting, precision is everything. For most of our clear bags, we use a method called die-cutting. We create a custom steel rule die, which is like a very sharp, industrial-grade cookie cutter in the exact shape of a bag panel. This die is pressed onto the material, cutting out a perfect piece every time. This guarantees that all panels for an order are identical. For very intricate designs, we might use a computer-guided laser. This precision ensures that when the pieces get to the assembly stage, they fit together perfectly, without any gaps or puckering.

How a clear makeup bag factory ensures flawless assembly and finishing?

Even with perfect pieces, how do they become a durable, beautiful bag? You are concerned about weak seams that split, crooked zippers, and sloppy logos that make your product look unprofessional and cheap.

Flawless assembly is achieved through professional techniques and constant quality checks. Strong seams are made with high-frequency welding, zippers are expertly stitched by skilled workers, and branding is applied precisely before a final, rigorous inspection of every single bag.

This is where skill and technology come together. For clear TPU bags, the strongest and cleanest seams aren't stitched; they are welded. We use a process called high-frequency welding, where electrical energy is used to fuse the TPU panels together at a molecular level. This creates a waterproof, incredibly strong bond that will not split or tear. It’s a technique that requires expensive machinery and skilled operators. Next comes the assembly line, where different specialists handle each step. One worker might be an expert at precisely printing the logo. Another is skilled at sewing in the zippers, ensuring they are perfectly straight and operate smoothly. After a bag is fully assembled, it’s not done. It goes to our Quality Control (QC) team. They follow a checklist, inspecting every detail: the clarity of the material, the strength of the seams, the smoothness of the zipper, the alignment of the logo, and trimming any loose threads. Only bags that pass this 100% inspection are packed for shipping.

Sustainable practices at a clear makeup bag factory you can trust?

You want your brand to be sustainable, but how do you know if your factory shares your values? You fear partnering with a manufacturer that engages in greenwashing or has wasteful, environmentally harmful practices.

A trustworthy sustainable factory prioritizes eco-friendly materials like biodegradable TPU, minimizes waste through precision cutting and material recycling, and operates with social responsibility. They provide certifications and transparency to prove their commitment to a green mission.

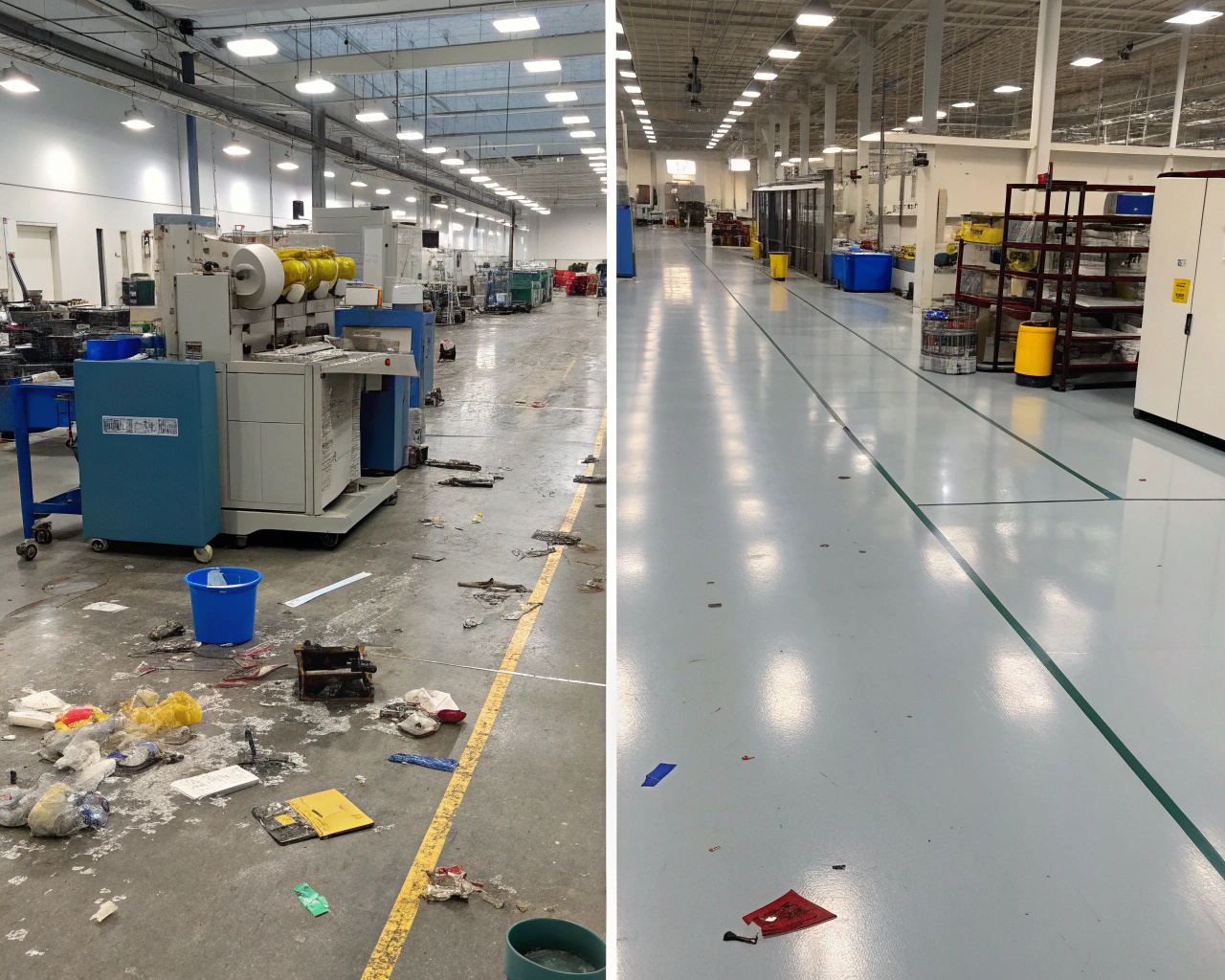

Sustainability is more than a slogan; it's a series of deliberate actions. Our "Green Mission, Global Win-Win" philosophy drives our daily operations. First, it starts with a material-first approach. We actively guide our clients, like Alisa, away from harmful PVC and towards superior, recyclable, and even biodegradable TPU options. Second, we are obsessed with minimizing waste. Our precision die-cutting methods are designed to lay out patterns in a way that maximizes the use of every roll of material. Any leftover scraps of pure TPU are collected and sent to be recycled into other industrial products. Third, sustainability includes people. This means maintaining a safe, clean, and fair working environment for our skilled team. A happy, stable team does better work and is part of a healthy, sustainable business. We believe in providing full transparency and are always ready to share our material certifications and talk about our processes. True sustainability is built on trust and tangible actions, not just words.

Conclusion

The journey from raw material to a flawless bag is a detailed process of choices. Choosing a quality-focused, sustainable factory ensures every step is done right, resulting in a product you’re proud of.