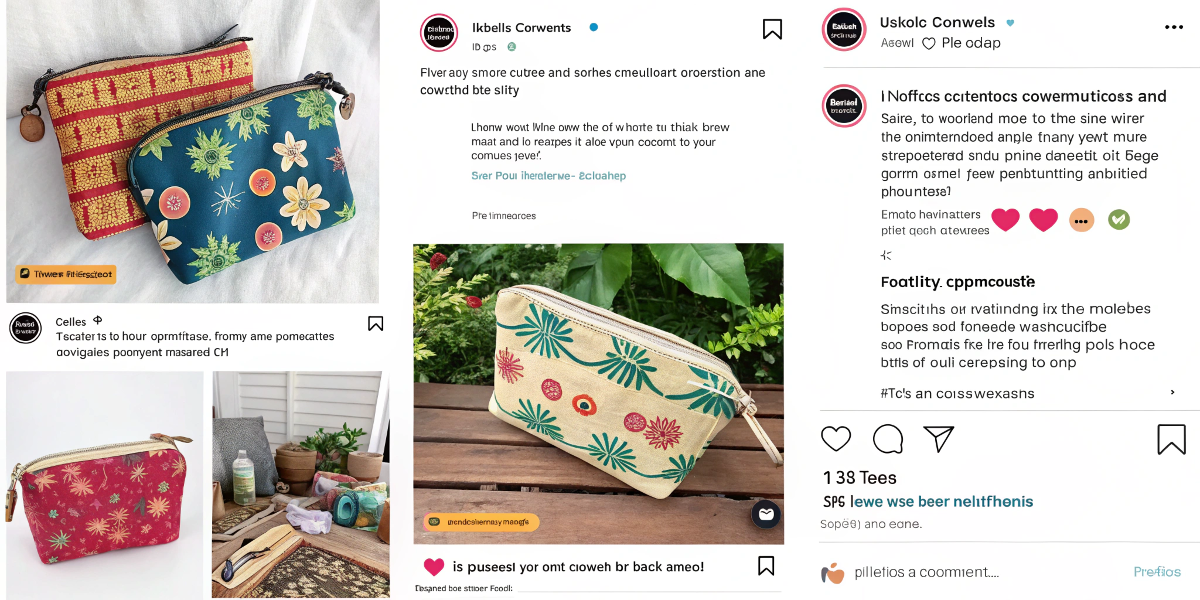

Case Study: How We Helped a Startup Beauty Brand Launch with 500 Custom Makeup Pouches

You have a powerful brand vision but a startup's budget. Finding a manufacturer willing to produce a small, custom order seems impossible, stalling your launch plans.

We helped a startup launch by acting as a collaborative cosmetic bag supplier. We focused on smart material choices, a streamlined design process, and accepted a low 500-unit MOQ, turning their premium vision into a budget-friendly reality without compromising on quality.

Over my 15 years in product development, I’ve seen countless amazing ideas from startup founders who hit a wall with manufacturing. The industry standard Minimum Order Quantities (MOQs) can be a huge barrier. At Rivta, we believe in being a true partner, not just another name in a long list of cosmetic bag suppliers. Our mission is about fostering growth and making high-quality, sustainable production accessible. This case study is about a new beauty brand with a fantastic concept, a clear vision, and a need for just 500 pouches to launch their first product. Let's walk through how we made it happen together.

What Was the Challenge in Turning Their Brand Vision into a Production-Ready Design?

The brand had a stunning vision. But they faced a classic startup dilemma: how to create a high-end product on a tight budget with a very small first order.

The main challenge was balancing their desire for a premium pouch—with a unique feel and custom color—against the production realities of low MOQs. Many cosmetic bag suppliers would simply turn them away, but we saw an opportunity to find a creative solution.

The founders came to me with a beautiful brand deck. They wanted their pouch to feel organic, luxurious, and unique—a true reflection of their clean beauty brand. Their vision included a custom dusty rose color, a specific textured fabric, and elegant, minimal branding. The problem was that ordering custom-dyed fabric usually requires a massive minimum order, far more than the 500 pouches they needed. They worried they would have to compromise their vision by using a generic bag that didn't represent their brand. My job was to bridge that gap between their creative vision and the practical realities of production. I wanted to ensure we didn't lose the magic along the way, proving we are the kind of cosmetic bag supplier that finds solutions.

The Core Challenges

We identified three main obstacles to overcome.

- Material Sourcing: Finding a sustainable, textured fabric that could be produced in a custom color for a small run.

- Cost Management: Keeping the unit price low enough to fit their launch budget without the bag feeling cheap.

- Branding Execution: Translating their minimal branding aesthetic onto the product in a way that was both elegant and cost-effective.

How Did We Collaborate on Materials and Prototypes with a Low MOQ?

The brand was stuck. They needed a partner to guide them through the complex world of materials and production, not just a factory to take an order.

We held collaborative sessions to select an in-stock, GRS-certified recycled canvas with a beautiful texture. We then custom-dyed the finished pouches instead of the raw fabric, a clever solution that works perfectly for smaller quantities.

This is the part of my job I love most—solving the puzzle. Instead of focusing on what we couldn't do, we focused on what we could. I sent the client a curated box of our in-stock sustainable fabrics. They fell in love with a 12oz GRS-recycled cotton canvas for its substantial feel and subtle texture. To solve the custom color issue, we used a technique called garment dyeing. We produced the 500 pouches in the fabric's natural, undyed color and then dyed the finished bags to their exact dusty rose Pantone shade. This process is much more economical for small batches. We then created a full, pre-production sample. This allowed them to hold it in their hands, test the quality, and approve every detail before the full run, giving them complete confidence.

Our 3-Step Solution

This partnership approach made all the difference.

- Guided Material Selection: We listened to their needs and provided a curated selection of in-stock fabrics that met their criteria and were suitable for a low MOQ.

- Creative Production Techniques: We suggested post-production garment dyeing to achieve their custom color without the high cost and MOQ of milling new fabric.

- Risk-Free Prototyping: We created a complete physical sample for their approval. This ensured the final product would be exactly as they envisioned, eliminating surprises.

What Key Details Brought the Final Custom Pouch to Life?

Every element on the final pouch needed to feel intentional and premium. The challenge was achieving this high-end feel using cost-effective components and processes.

We focused on elevating simple components. We chose a high-quality stock zipper with a matching puller, used a simple woven label for branding, and ensured the stitching was perfect. These details created a premium product without the cost of custom hardware.

When you build a product, you realize that luxury isn't always about bold, expensive features. Often, it's about the quality of the small, simple things. For this pouch, we knew a custom-molded zipper pull was out of budget. Instead, we sourced a high-quality YKK zipper with a standard, minimalist metal puller and had it dyed to perfectly match the dusty rose fabric. For the branding, we suggested a small, folded woven label sewn into the side seam. This is a classic and cost-effective branding method that looks incredibly chic. The final touch was the craftsmanship. Our skilled sewers at Rivta ensured that every stitch was perfectly straight and clean. As their cosmetic bag supplier, we understood that this attention to detail is what makes a simple bag feel truly special.

Final Product Specifications

These carefully chosen details resulted in a beautiful and affordable final product.

| Component | Specification | Why It Worked |

|---|---|---|

| Main Fabric | 12oz GRS Recycled Cotton Canvas | Sustainable, provided a luxe texture, was an in-stock material. |

| Color | Custom Pantone Dusty Rose | Achieved through garment dyeing to accommodate a low MOQ. |

| Branding | Tonal Woven Label on Side Seam | Elegant, minimal, and highly cost-effective for a startup. |

| Closure | Color-Matched YKK Nylon Zipper | Reliable quality and a seamless look without custom hardware costs. |

| Construction | Reinforced Stitching, Simple Flat Pouch | High-quality craftsmanship on a simple, efficient design. |

What Was the Result of the Launch, and How Did It Create a Blueprint for Growth?

The startup invested its limited capital into this first run. A failed launch could mean the end of their business before it even began.

The launch was a huge success. The 500 custom pouches were a key part of their product bundle and sold out within the first month. This validated their brand concept and secured funding for a larger, second production run.

The best part of my job is seeing a brand I've worked with succeed. Because we found a way to create their dream pouch at an accessible price, they launched with a product that perfectly communicated their brand's vision. The pouches were featured all over social media, and feedback from their first customers was amazing. People loved the color, the fabric, and the overall quality. This success gave them the confidence and sales data they needed to place their next order—this time for 5,000 units. They now have a trusted manufacturing partner in us and a proven production process. We have a blueprint that can scale with them as they grow, solidifying our role as a long-term cosmetic bag supplier for growing brands.

From Launch to Long-Term Partnership

The successful first run created a clear path forward.

- Proof of Concept: The quick sell-out proved there was a market for their product and aesthetic.

- Established Supply Chain: They no longer have to vet dozens of cosmetic bag suppliers. They have a partner they can trust.

- Scalable Model: We can easily scale up production for their next run and explore more complex customizations now that they have a larger budget.

Conclusion

This case study shows that with a collaborative partner, a low MOQ is not a barrier. Smart choices can turn a startup's unique vision into a successful, high-quality product launch.